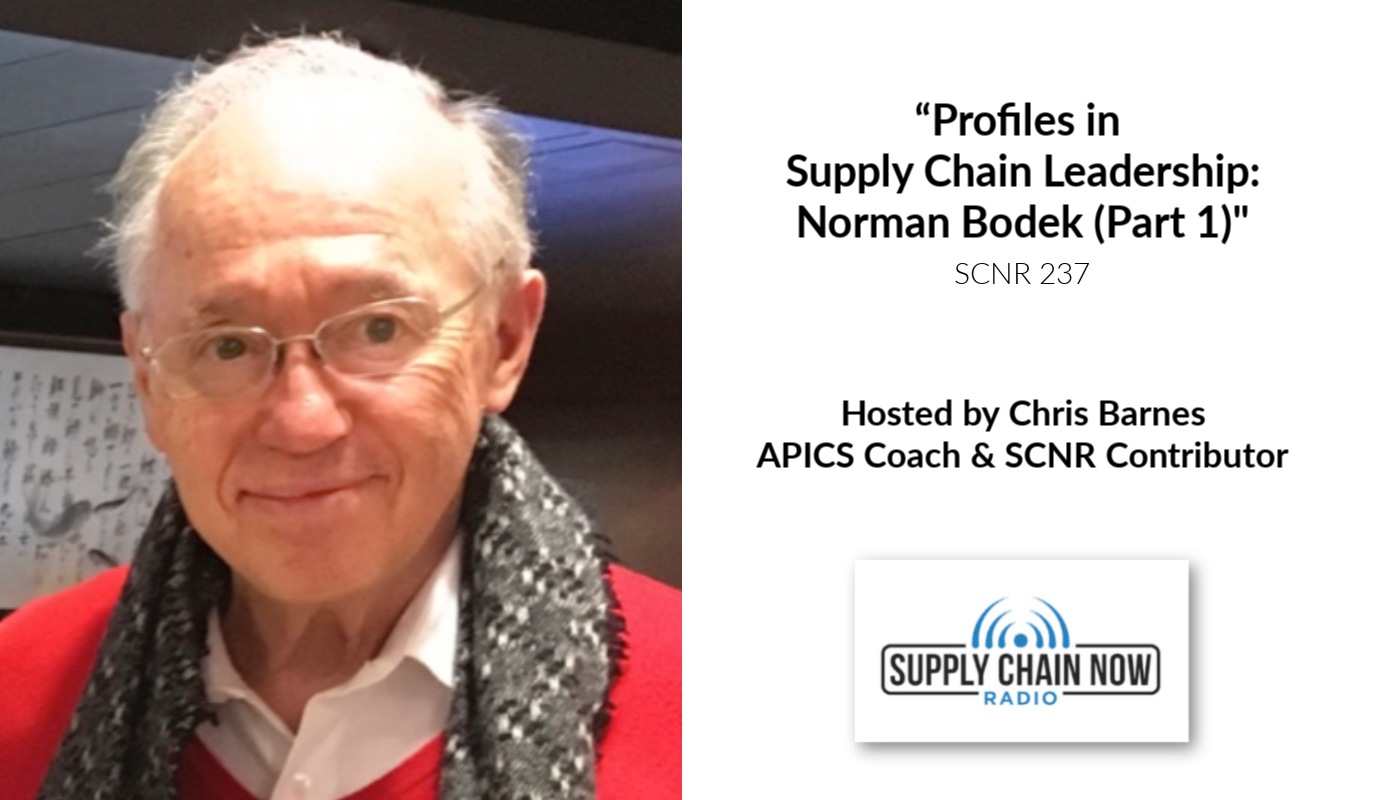

Supply Chain Now Radio Episode 237

Supply Chain Now Radio, Episode 237

APICS Coach and SCNR Contributor, Chris Barnes, welcomes Norman Bodek to Supply Chain Now Radio in the next installment of the Profiles in Supply Chain Leadership series.

[00:00:05] It’s time for Supply Chain Now Radio. Broadcasting live from the Supply chain capital of the country, Atlanta, Georgia. Supply Chain Now Radio spotlights the best in all things supply chain the people, the technologies, the best practices and the critical issues of the day. And now here are your hosts.

[00:00:29] Hey, it’s Chris. The Apex coach and contributor to Supply Chain Now Radio.

[00:00:33] In the early 90s, I was involved with the implementation of a con biomaterials management system for a company converting to a just-in-time environment. A key part of my role was educating over 300 employees on the concepts of Jay EITI. At the time. I didn’t know what I didn’t know, but I invested many hours reading and learning about Jay EITI and what is now commonly referred to as Lehne. After 20 plus years of teaching the apex body of knowledge. I decided to try and interview some of the great thinkers I’ve been learning from for so many years. After a little research, I realized two things. One, many of the people are deceased and too many had one person in common. Norman Bozek, the godfather of Lean. Norman Beaudet is a teacher, consultant, author and publisher. He published over 100 Japanese management books in English, including the works of Taichi Ono and Dr. Shogo Shinjo and taught the best of Japanese management at Portland State University. Norman created the Shinjo Prize with Dr. Vern Buehler at Utah State University. He also was elected to the Industry Weeks Manufacturing Hall of Fame. I recently sat down with Norman to get a better understanding of his impact on Lean and some of his current thoughts. Take a listen to this three-part part interview with Norman. I hope you enjoy listening as much as I did getting to know The Godfather of Lane and you got to love his laugh.

[00:01:55] First, I want to thank you very much, Chris, for doing this with me, and you are an amazing person. You probably did more research about me than anyone in my entire life. And I thank you so much because I’m going to use it. Now I’m writing a whole new book and I’m going to talk about this new book because I think it’s going to be very important. It’s sort of my legacy since I’m eighty seven, probably take me a year to write it, but I want to leave something very good for this for this world that gave me so many good things. And we’ll talk about this new subject, which is the whole revolution that’s happening in America.

[00:02:33] Well, it’s interesting, as I was as I’ve gotten to know you just in the past few months, and I’m I teach the lean to students. I didn’t realize how much lean not only meant to profits and productivity, but it also means to the people, the personality, it’s improving the quality of life for their work.

[00:02:50] Of course, if we continue in the right direction and we we want I’ll get into lean with you. Let me just talk a little bit about this new revolution with CEOs in America. Back in 1970, Milton Friedman, he was a professor at the University of Chicago and he was awarded the Nobel Prize for a number of things he did in economics. But he said 1970 that a CEO, a corporation, has only one responsibility, and that is to make profits for the shareholders. That’s it. The corporation doesn’t have to be goody goody. It doesn’t have to be concerned about the environment or people. Not at all.

[00:03:32] That could come later if the investment. If the investors want to take that money and do good things with it, that’s up to them. But the obligation of a CEO is to make money. And they did since 1970, close to 50 years. The corporations in America have become enormous. We know many of them are real monopolies throughout the world. And and they’ve made enormous profits. And the CEOs back in 1970, the average top CEO made 20 times the average worker, the average worker say made thirty thousand dollars. The average CEO made six six hundred thousand dollars today. It’s close to 200 times 20 to 200 down to the average worker’s making 50 or maybe even more because the average CEO’s making fifteen point six million dollars around that. So they’ve done very well with Milton. Milton Friedman philosophy. But man called Lawrence Think. Lawrence Think is the chairman of a company called BlackRock. Probably one of the world’s largest investing companies. Mazing company. They own trillions of dollars of assets. And what Lawrence thinks said Larry King said last year, is that we these corporations have to become socially responsible. He’s not telling him to make less profits. He’s not telling them to take less compensation. But you have to become more socially responsible because look what’s happening in the world. The companies are getting richer, but people are getting poorer and society is suffering tremendously, especially with the environment.

[00:05:16] He said he control so much of America’s assets that he could tell a company like Apple. If you don’t become socially reliable, I’ll sell your stock if I sell your stock. That could be tragic for Apple or any other company. Because I’m not going to continue my investment, he said, unless you become socially responsible. Now, Chris, it took about a year, but one hundred and eighty one out of the top 200 companies that belong to the Business Roundtable, which is a group that represents and educates these top CEOs. One hundred and eighty one of these said, yes, we will become socially reliable. We will refocus differently on our customers to make sure they are satisfied. We’re going to relook at what we do with our employees. So they begin to train them, begin to trust them, begin to expand their capability. We’re going to relook at our relationship with our suppliers. Suppliers now we’ll become partners, not adversarial people. We’re going to relook at our communities. We’re going to relook at the environment. And of course, we’re going to continue to make profits for our shareholders. This is very dynamic. This is going to give a whole new set of opportunity for all of us.

[00:06:36] Norman, from an ethics perspective, we we actually teach that in our classes now. It’s more more so in recent years, but we call it the triple bottom line, which is get another book that we talk about how corporations have not only a profit responsibility, but a responsibility to the planet and also responsibility to the people. So those the three measures that companies really should be looking at now.

[00:06:58] Well, that’s wonderful where we’re going in the right direction. But these corporations have led the world and they led the world and we’re in trouble. I mean, these species are dying. You know, there’s so many inherent problems to. Japan had more rain in the last week than they’ve ever had in their history. Paris had the highest temperature that they ever had to quit. Time is so hot at this moment, they’re trying to air condition the air around them. Yes, we’re all in trouble in the environment and we have to refocus. And I’m glad that a fix is there. Now these corporations are going to be there. It’s gonna require a whole new role of supervision. So a manager or a supervisor, instead of looking to control people, they’re going to have to make a dynamic shift to bring out the best from people. Yes. We’re going to rethink that people for a real asset. We say that, but we don’t do it. Well, I’m writing a new book on the subject, you know. And we say that people are assets. But look at your balance sheet. There’s no people on the balance sheet. There is no customer service on the balance sheet. There is no supplier relationships on the balance sheet. There is no advantage for a company to invest in the environment because it’s not on the balance sheet. So this could be a radical Lu shift. We’ll talk more about it together as we go through this. I want to mention my gratitude to apic apic played monumental events in my life. One day I I was with Shingo in Las Vegas and we we Apex asked me to get shingled the keynote conference for them. And so we had about 3000 people in the audience, something like that. And this is very funny because I would take single around. Well, I got early. UPS early, very early in the morning to go get Dr. Chignon in the time to get breakfast or change or needed three bananas. He liked to use in his talk.

[00:08:59] Well, I was hungry, so I took one of the bananas and I atum I thought two’s enough. A single single gets up in front of the three thousand people in APICS. I don’t know what to do because Norman totally destroyed my talk. My whole talk is based on three bananas.

[00:09:15] But Norman 8:1, one of his props. One of these props. Because why was he talking about bananas? Because when you were referring to what lean is all about getting lean.

[00:09:27] And what we want in a banana is the content, we don’t want the skin, we don’t eat the skin. So why should we pay for the skin? And this was his analogy to dustbin time and the total production system, what we call lean. Why should people pay for waste? Yes, we might need certain things we need covering. But why do the customer pay for that coverage? Right. Should they pay for their weight? Another time with Apex is Apex. Who’s going to have their conference in New Orleans? But they’ve got pretty much destroyed by other BYO by the hurricane. So they switched to Kansas City. And I had the opportunity to keynote the conference in Kansas City. At that time. I had about 700 people in the audience.

[00:10:10] I had a wonderful time with them because, Chris, I sold more books than I ever sold in my life. At that moment. I sold two hundred and forty copies of the books. Never happened before in any previous conference. That was an amazing event. So I’m really in so many ways, the people of Apex. Thank you. And I hope you make a lot of value out of this discussion.

[00:10:33] I didn’t realize I was reading a lot of your published books. You know, whether it’s just in time or lean or or the waste or anything on shingle. How did you come to know these people?

[00:10:43] Well, it’s interesting, you know, Chris, because like I said, I started off as the dumbest kid in school. You look at my ninth grade report card. I was such a poor student. We can talk more about that. But it’s miraculous in my life. I’d been like a magnet for greatness. A magnet for greatness. I am so grateful for the amazing people I’ve met.

[00:11:05] Oh, what’s what’s interesting on that. I was reading your look at your latest book, A Miraculous Life. And I kind of realize you you personally in your in your life, you kind of have a continuous improvement mentality. And I don’t know if that’s was developed or was just something you had forever.

[00:11:20] I’m very grateful. You know, when I started back in nineteen eighty one, we’ll talk a little bit more about it when I started productivity. America was a productivity growth leader in the world and Japan was slowly, slowly catching up. And when we compared Japan in America it was like comparing the tortoise with the hare, you know the turtle with the rabbit. And the rabbit was so fast when they raised the rabbit. You know, I was fooling around and fell asleep on the side of the road and the turtle just kept moving forward slowly, slowly moving forward. And all of a sudden they’re way ahead of us. It’s like me in my life. You know, I just keep plodding forward. Sure. I had a lot of I had main problems and we’ll talk about that. One of my favorite stories is Pinocchio.

[00:12:08] And you know, Pinocchio wanted to be a real boy, well, Norman wanted to be a real boy. And I wasn’t because I was such a poor student. I wanted to be a real boy, not a puppet, not a puppet of my parents or my teachers. I wanted to be a real boy and Pinocchio wanted to be a real boy.

[00:12:23] But the problem with Pinocchio and the problem with Norman Pinocchio didn’t listen to his conscience pricked Jiminy Cricket. Well, everybody has a great a great cricket inside them. You have something deep inside. You will guide you if you could learn to listen to it. It’s not the 70000 thoughts you get in your head every day. No.

[00:12:45] This computer of yours is while your computer records everything in your life and it keeps throwing it up at you as if you need it. Well, you don’t need all of that. The mind is wonderful if you learn to use it. The same thing with your conscience inside me is a great conscience. But I never learned through life how to really appreciate it. I would listen to all the other people just like Pinocchio, you know, I would listen to the to the sly fox. The other thing they wanted to take him to the to to acting or to play land, of course, or play land. All the children turn into donkeys. Well, that’s true in our life. You know, we have such opportunity for greatness. And we want to go to Las Vegas. We want to go to the play lands. We all want to have a lot of fun in life. Instead of really where we should be is we all should be growing. We all should be learning. We all should be growing. And that’s true. Every single day, you should have a very clear goal of what you want to be in this life to be successful. Pick just one skill. Doesn’t matter as long as that skill will serve people. It doesn’t matter. You pick something that you want to be the greatest in the world.

[00:13:59] That and you. You never, never, never give up what you need. That goal. And most of us don’t have a goal. Anything is great. There’s a jumping around a lot. But Japan loves contests. They have contests on everything. And I recommend you think about having contests in your company. How much fun this is to motivate people to get excited about things that they do. We should go to work and get excited the same way when we go to the football field. One hundred thousand people go to Michigan to watch a football game because it’s exciting for them to watch it. And I love football, but we should be so excited when we go to work. And what we’re missing is the same thing. We need a good contest. Japan has contests for everything. They even have contests of the best cleaning people in Japan. This is amazing. The cleanest airport in the world is Haneda Airport. That’s the Tokyo Airport. Five years in a row, they’ve been rated as the cleanest airport in the world. And they identified one woman who’s in charge of cleaning. She cleans the toilet. And they had a national television show just on her. What she did to clean up the airport so that their airport was nominated. Five years are always the best in the world. We should do the same thing.

[00:15:13] Is honor people that way. What’s that of big impression on you as the Japanese relationship with Japan or having visited Japan many times? And that’s where you had the opportunity to meet some of these great thought leaders. So how did that happen?

[00:15:26] You’re also lucky back in nineteen seventy nine. I got fired. Funny story. I got fired. The president, the data processing company, I didn’t know it, but I was present level. I ran it. I took it from nothing to to a multi-million dollar business. And one day the owner of the company woke from Nelson. I just went out to Indiana and I signed up a very big contract for the company. Indiana Bell, the telephone company. I’m sitting on the airplane with Wolf and won’t turn to me. Norman, you did such a great job. I don’t need you anymore. You’re fired. Well, funny thing is, I was not unhappy. I didn’t like working for Walter at all. And Walter had to pay me for three years more. So I wasn’t panicky. I mean, he wasn’t very nice. I was supposed to get 7 percent of the sales, but we sold up millions of dollars of business. He didn’t want to pay me the 7 percent. So I was sitting around a couple of months later trying to figure out what am I going to do in my life? And I read The New York Times financial section. I don’t know why. Because I wasn’t interested in the financial section at the time. But I looked at it and it was a headline said Productivity declined in America for the first time in thirty three quarters.

[00:16:34] Sounded important. Had no idea what it meant. I was so curious. I went to the library. Then I never go to the library. It’s funny. I hardly. I love books. I buy thousands of books, literally. But I don’t go to the library. When I went to the library, study the word productivity and found very, very, very, very little. I kept studying. Why is it so important? And then I noticed Japan was a productivity growth leader in the world. And I decided even though I wasn’t a writer, I’m going to start a newsletter called Productivity. Well, I went to a friend of mine. A friend of my teacher name is Milton Glaser. Milton Glaser was probably the most famous illustrator in America. He did Dylan covers. He was the one that created the I love New York. You know, that that famous that famous sign. And I went to Milton says, I’m going to start a new company called Productivity and I need a logo. And Milton Glaser gave me a logo. The most famous designer probably would’ve charged twenty thousand dollars to somebody else. I paid hardly nothing. And I got a wonderful logo which gave people the impression that I was real. And then Milton gave me a list.

[00:17:42] Do you know him or you just reached out to him because he was a leader?

[00:17:45] No, I knew because he was the best friend of my teacher. I’ll talk about ludie when we go through this, too. What I’ve learned from Rudy, this great teacher that I had. And Milton and Milton was probably Rudy’s best friend. So that’s how I knew him. And then Milton gave me very nicely a list of 10 things that I could do to write a newsletter. And I followed them precisely. And I said, Milton, would you give me the logo? He said, yes. But I have to write the newsletter. So I and another man, he was actually the librarian.

[00:18:15] He got so interested in me because I kept going to the library research and he helped me with the research. You get all excited about productivity that he left the library to join me as my head because I couldn’t write at all. It’s funny the way I track this thing. And we spent the next month writing a 12 page newsletter just for Milton Glaser. And we did it and we brought it down to him and then he gave us the logo. And so I started a company called Productivity since Japan was the productivity growth leader. I had to find out what Japan was doing. I couldn’t find out in the library. Nothing. So one day I’m talking to a teacher of mine and he says, Norman, you’ve got to go to Japan.

[00:18:55] I said, how can I go to Japan? How can I? I don’t know anybody. I don’t know the language. He says you’ll figure it out. That was a wonderful thing he said to me. That’s what we should tell everybody. You will figure it out. You will trust yourself. You will figure it out. We don’t do that. We tell people everything. You always talk about the power of Ono. Very similar to that. And it’s miraculous because a month later, Chris, I went to a workshop in New York City run by Industry Week, which has played amazing role in my life and industry by 100 people, which showed up in New York City and a speaker there was Joe Jerai and he was the manager of Japan Productivity Center. And they had an office in Washington. They were here. His main purpose was to get American companies to open up and allow Japanese managers to come and visit. And that’s what he was talking about. And many companies in America just opened their doors. So we had no idea what we were doing. We had such good hearts. We opened our hearts. We let the Japanese come over. And of course, they would visit our plant. And then they would say to the plant manager, could I take your picture? And of course, you know, it was already Gates mystical that we say, please, you can take my picture. And then the Japanese say, could you move over a little bit? Just move over to the side a little bit. They didn’t want you, they wanted the machine behind you. And they learned so much from us. They went back and replicated it. One hundred percent. I remember I did a lot of work with Japan Management Association later amaa.

[00:20:30] They went to the A.M.A. in New York City where I used to teach at the A.M.A.. They took pictures of everything and they went back to Japan and they opened up and they expanded Japan Manager Association and their building. They made all of the classrooms exactly what they sought at the at the A.M.A.. Exactly. Even though the Japanese are small of people, they make the desks the same size. This was very funny. Japanese copied us. And, of course, what they did next, Chris, after they copied us, what’s the next step? They improved. Of course they improved it. That’s the trick. We improved processes, continuous improvement. We talk about, well, the first thing that you should do, ladies and gentlemen, is improve yourself. You become great. You become an expert in something. Doesn’t matter. And yes, there’s always going to be resistance standing in your way. It’s gravity. Gravity pushes, you know, less. You stand on the earth and there is resistance. And the biggest resistance, of course, is your mind. What are you afraid of? But everybody’s afraid. There’s nobody on. Maybe Rudy was the only one that I met that wasn’t afraid. Everybody’s if you go to work, you’re afraid because in the American society, we build on that. Right. We don’t give you power. We hate unions. We hate themes. Even quality control circles are so great, but we don’t do it in America. Why? I don’t think companies like people getting together. We don’t like dispersing power. We want power to stay with management. And we don’t. We don’t like this idea of giving people too much power.

[00:22:09] In a story of Japanese coming here and taking the pictures and then improving, that reminded me of something. You probably know if this is true. Demming, who tried to sell its quality philosophy in the States, they couldn’t get applied. So we went to Japan and that’s where he became famous.

[00:22:22] He has a funny part of my in my story in Demming because my problem is always listening to somebody else instead of listening to my heart. I went to New York University Graduate School of Business, a miracle from a DOMAs kid and I get into graduate school. Deming taught there and I was gonna take statistics in the next semester. I’m talking to Howard, this friend, so-called friend of mine. So I say so-called because stupidly I listened to Howard and Howard had no idea what he was saying. Howard said, Norman, don’t take statistics is too hard. I’m very good at math. But somehow I was afraid, afraid, afraid, because if I flunked out of graduate school, I’d have to go into Korean War. And that kept me in check. That kept me in graduate school. Listen to Howard. And I didn’t take statistics and Dr. Demings taught the course. I could have had Demming 30 years before. Yes, I met Demming. I went out of my way to meet Demming. Demi was invited to Japan 1959. It was 1959, maybe earlier, maybe 1950. McMaster brought him over. MacArthur was a very unusual general because most most countries, when when they win a war, they just milk, milk, everything out of the society they built. Well, MacArthur wouldn’t do this. MacArthur rebuilt Japan and he brought over people to help Japan and he brought over Demming. And Demming was approached by the quality organization called Juice Japanese Union, the Sciences and Engineers.

[00:23:48] And they said Dr. Deming will get three hundred and fifty people to listen to three hundred and fifty engineers to listen to you. And then he said, no, I want 350 CEOs. Miraculously, they did it. They got three hundred and fifty CEOs of the Japanese top corporations to come and listen to Dr. Deming. And Deming taught them the power of quality. And they said to Deming, what could we do to catch America? And he said, look, you take my advice. You focus on quality, you learn statistical quality control. You make sure that your process or run are stabilized. You make sure that you’re producing the highest possible quality you see at that time. Chris, we had a standard in America which was plus 3 percent plus or minus 3 percent. It was okay if you produced 100 items. 3 could be wrong. So when I had my first conference, I ran a conference, my first conference. I ordered 200 notebooks and I got two hundred and thirty notebooks. And I say, why did you send me all these extra notebooks? And they say, because a number of the notebooks you get are not going to work. That was the American way. Deming said, no, you can’t do that. And they listen to them. And then at the end of his talk, they said to Deming, that’s a very powerful man. His name was Ishikawa is a coward. It really was the one who invented what we call total quality management.

[00:25:12] And it’s a car invented quality circles. And they said. We want to reward you, gonna give you money if your talking Demings. No, I don’t want your money because there is paying me enough. You take that money and set up a prize. And they did. They set up the Demming Prize and every major company in Japan competed for that Demming prize. And that competition is great. That’s why I started a number of years later, the single prize. I said, America, we need the same thing. We need a prize to focus on improving our productivity. And very luckily, very. Bueller was a professor at Utah State University and very Dula said to me, normal. I want to get Shingo to come and talk at the conference. I said, I’ll get Shinjo. But during you got to do two things. You’re required to do two things to get Singo one. I want you to start a prize called the single prize. I want you to get him an honorary doctorate degree and virtuous. Norman, I’ll try. Well, sure enough, he did it. He got Utah State University to give Dr. Singo an honorary doctorate degree. And we started the prize together called the Shinjo Prize this year. Chris, I went to Cincinnati. There was six hundred people at their conference. Single price conference. I’m very grateful. They’re very, very successful that many of American companies are really competing to be better to improve their productivity and growth.

[00:26:34] It’s ironic. The US has a Japanese based surprise shingled prize. And then Japan as a U.S. based prize, which is the Demming prize.

[00:26:42] Well, foreign is always better. You know, this old saying a profit is never known into our own house and we appreciate the things that are more mystical and far away.

[00:26:53] This concludes part one of the three part series with Norman Vote Act, The Godfather of Lean. In part two, we learned about the power of asking how can I help you? Demanding the impossible.

[00:27:03] The supermarket and single minute exchange of dyes.

Norman Bodek is President of PCS Inc. In 1979, after working for 18 years with Data Processing companies, Norm Bodek started Productivity Inc. – Press by publishing a newsletter called PRODUCTIVITY. At the time, he said he knew virtually nothing about the subject and had spent very little time in manufacturing facilities. But, he quickly became fascinated with the subject and went to Japan to discover the processes that was making Japan the world leaders in quality improvement and productivity growth. Even though on his first visit to Japan he didn’t know a single person or speak Japanese, he has since, in the last 31 years, gone to Japan 80 times, visited more than 250 plants and published more than 100 Japanese management books in English, and over 150 other management books. As a fortune cookie once told him, “You have the talent to discover the talent in others.” Mr. Bodek said his claim to fame is that he found amazing tools, techniques and new thoughts that have revolutionized the world of manufacturing. He has met Dr. W. Edwards Deming, Dr. Joseph Juran, Phil Crosby, Dr. Kaoru Ishikawa, Dr. Joji Akao, Mr. Taiichi Ohno, Dr. Shigeo Shingo and many other great manufacturing masters and published many of their books in English. Each person he met gave him a new perspective on continuous improvement. Mr. Bodek has lead over 25 study missions to Japan and was one of the first to find and publish books, training materials and run conferences and seminars on TPS, SMED, CEDAC, quality control circles, 5 S, visual factory, TPM, VSM, Kaizen Blitz, cell design, poka-yoke, lean accounting, Andon, Hoshin Kanri, Kanban, and Quick and Easy Kaizen. Mr. Bodek, who was once called “Mr. Productivity” by Industry Week Magazine, and “Mr. Lean” by Quality Progress Magazine, said his most powerful discovery was the way Toyota and other Japanese companies opened the infinite creative potential often lying dormant inside every single worker. Most recently, he worked with Gulfstream Corporation, a private jet company, where 1000 people that went from 16-implemented ideas in February 2005 to close to 40,000 in 2011, and resulting each year in annually savings of over $2 million. Mr. Bodek founded the Shingo Prize for Operational Excellence at Utah State University with Dr. Vern Buehler and is one of the few to be personally awarded the Shingo Prize. He also was inducted into Industry Week’s Hall of Fame. In the last 10 years, he has written hundreds of articles published in various magazines and journals and on management web sites. Norman has written seven books: “The Idea Generator – Quick and Easy Kaizen,” and “The Idea Generator Workbook,” co-authored with Bunji Tozawa, president of the HR Association in Japan, “Kaikaku the Power and Magic of Lean,” Rebirth of American Industry, co-authored with William Waddell, and “All You Gotta Do Is Ask, co-authored with Chuck Yorke, How to Do Kaizen, co-authored with Bunji Tozawa and most recently “The Harada Method – the Spirit of Self-Reliance,” co-authored with Takashi Harada. Learn more about Bodek’s firm, PSC Inc, here: https://www.pcspress.com/

Chris Barnes is a supply chain guru and the APICS Coach. He holds a B.S., Industrial Engineering and Economics Minor, from Bradley University, an MBA in Industrial Psychology with Honors from the University of West Florida. He holds CPIM-F, CLTD-F and CSCP-F designations from ASCM/APICS, one of the few in the world. Barnes is a professional education instructor for the Georgia Tech Supply Chain & Logistics Institute’s Supply Chain Management (SCM) and University of Tennessee-Chattanooga Center for Professional Education certificate courses. Barnes is a supply chain advocate, visionary, and frequent podcaster and blogger at www.APICS.Coach.com. Barnes has over 27 years of experience developing and managing multiple client, engineering consulting, strategic planning and operational improvement projects in supply chain management. Connect with Chris on LinkedIn and reach out to him via email at: [email protected].

Upcoming Events & Resources Mentioned in this Episode

SCNR to Broadcast Live at CSCMP Atlanta Roundtable Event: https://tinyurl.com/y43lywrd

Reverse Logistics Association Conference & Expo: https://rla.org/event/80

SCNR to Broadcast Live at MODEX 2020: https://www.modexshow.com/

SCNR to Broadcast Live at AME Atlanta 2020 Lean Summit: https://www.ame.org/ame-atlanta-2020-lean-summit

2020 Atlanta Supply Chain Awards: https://www.atlantasupplychainawards.com/

SCNR on YouTube: https://tinyurl.com/scnr-youtube

The Latest Issue of the Supply Chain Pulse: https://conta.cc/2rLkO5Y

Check Out News From Our Sponsors

The Effective Syndicate: https://www.theeffectivesyndicate.com/blog

Spend Management Experts: https://spendmanagementexperts.com/

APICS Atlanta: https://apicsatlanta.org

TalentStream: https://talentstreamstaffing.com/

Verusen: https://www.verusen.com/

Georgia Manufacturing Alliance: https://www.georgiamanufacturingalliance.com/

ProPurchaser.com: https://tinyurl.com/y6l2kh7g

Supply Chain Real Estate: https://supplychainrealestate.com/

Vector Global Logistics: http://vectorgl.com/